Welcome! ZZJG VALVE Factory Can Offer High Quality Line Blind Valves And Goggle Valves.

During the valve’s opening/closing process, there is no contact between the sealing surfaces of the valve body and the vane, so the sealing surfaces suffer neither friction nor wear, contributing to the valve’s long service life and small opening/ closing torque.

For the valve’s maintenance, its bottom cover is removed to replace the vane pair, thus it is very easy for the maintenance.

The valve is provided with an automatic bleed device (optional) which can prevent the abnormal pressure rise of the valve cavity and check the valve’s effect after the valve is completely closed.

The elastic seal on the vane is made of the fluorine rubber and molded and formed in a groove of the vane surface. The fireproof metal-to-metal seal is used as the backing of the elastic seal.

The professional 3D software for structural analysis, material selection and process planning to virtually simulate the reliability of materials under different temperatures, mediums andpressures, and finally validate them through finite element analysis to provide customers with safe and reliable products.

From raw materials to production, sealing performance testing, strength testing, functional testing, to surface quality testing and packaging and shipping, the whole process is strictly in accordance with API standards and support third-party independent organizations to test and certify our products.

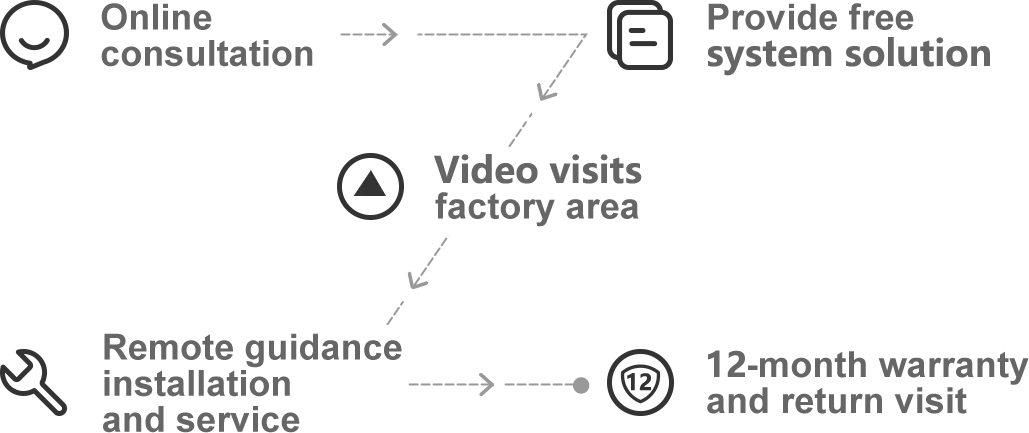

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!