Welcome! ZZJG VALVE Factory Can Offer High Quality Line Blind Valves And Goggle Valves.

More than 95% of automatic welding equipment is used. Each boiler is tested and quenched before leaving the factory. The qualified rate of inspection is 100%.

Maintains seal stability under thermal cycling or dynamic loads.

Simplified design reduces wear points; suitable for tight spaces.

Widely used in oil/gas, petrochemicals, and steam systems requiring durable, fire-safe isolation.

The professional 3D software for structural analysis, material selection and process planning to virtually simulate the reliability of materials under different temperatures, mediums andpressures, and finally validate them through finite element analysis to provide customers with safe and reliable products.

From raw materials to production, sealing performance testing, strength testing, functional testing, to surface quality testing and packaging and shipping, the whole process is strictly in accordance with API standards and support third-party independent organizations to test and certify our products.

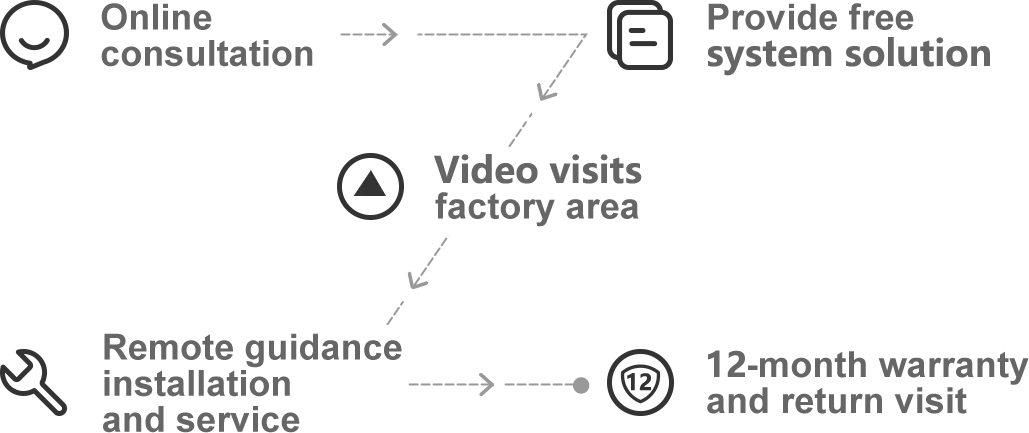

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!