Welcome! ZZJG VALVE Factory Can Offer High Quality Line Blind Valves And Goggle Valves.

Combines advanced materials (e.g., hardened alloys or ceramic coatings) to minimize friction and extend service life under abrasive conditions.

Incorporate thermal compensation mechanisms, enabling valve plate switching without disassembling or stressing adjacent pipeline components.

Millisecond-level actuation suits emergency isolation or flow direction reversal in high-pressure systems.

With modular design and bolt-free access reduces downtime and ensures long-term sealing integrity.

The professional 3D software for structural analysis, material selection and process planning to virtually simulate the reliability of materials under different temperatures, mediums andpressures, and finally validate them through finite element analysis to provide customers with safe and reliable products.

From raw materials to production, sealing performance testing, strength testing, functional testing, to surface quality testing and packaging and shipping, the whole process is strictly in accordance with API standards and support third-party independent organizations to test and certify our products.

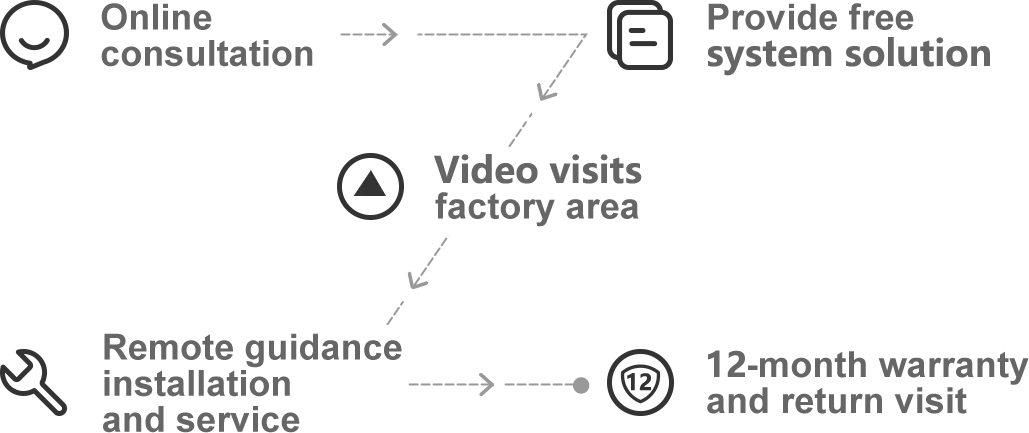

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!