Welcome! ZZJG VALVE Factory Can Offer High Quality Line Blind Valves And Goggle Valves.

Ensuring complete and verifiable fluid containment, eliminating leakage risks during maintenance or emergencies through dual-sealing mechanisms and independent isolation verification.

One person, one side, no bolts need to be removed. Simple operation with single-sided access enables one-person control and maintenance-friendly functionality, eliminating bolt removal for streamlined workflow.

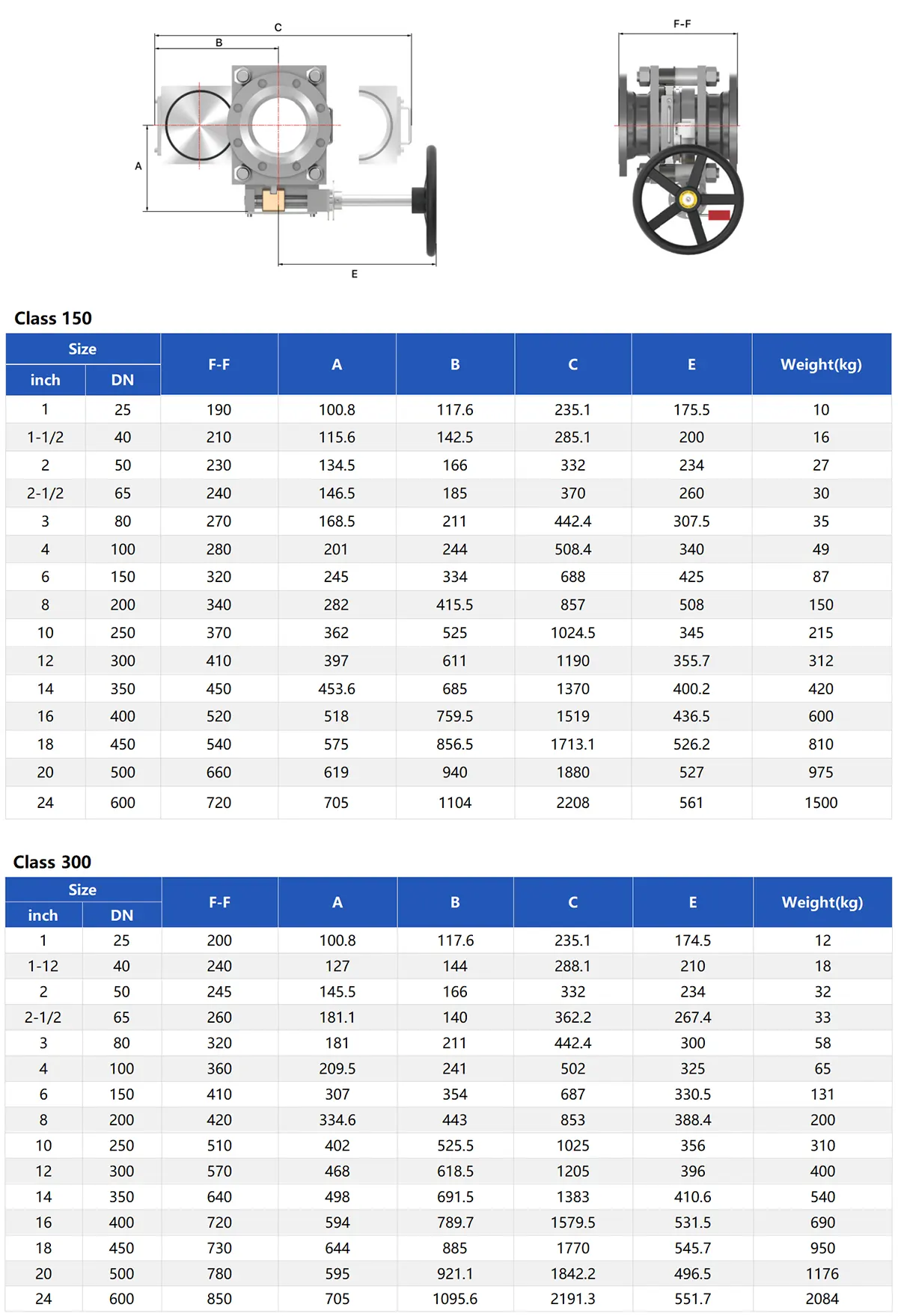

Ensures the valve integrates seamlessly into space-constrained installations while minimizing footprint and maintaining streamlined piping layouts.

Double Sealing in valves employs dual materials to ensure redundant leak-proof protection in high-pressure or corrosive environments.

The professional 3D software for structural analysis, material selection and process planning to virtually simulate the reliability of materials under different temperatures, mediums andpressures, and finally validate them through finite element analysis to provide customers with safe and reliable products.

From raw materials to production, sealing performance testing, strength testing, functional testing, to surface quality testing and packaging and shipping, the whole process is strictly in accordance with API standards and support third-party independent organizations to test and certify our products.

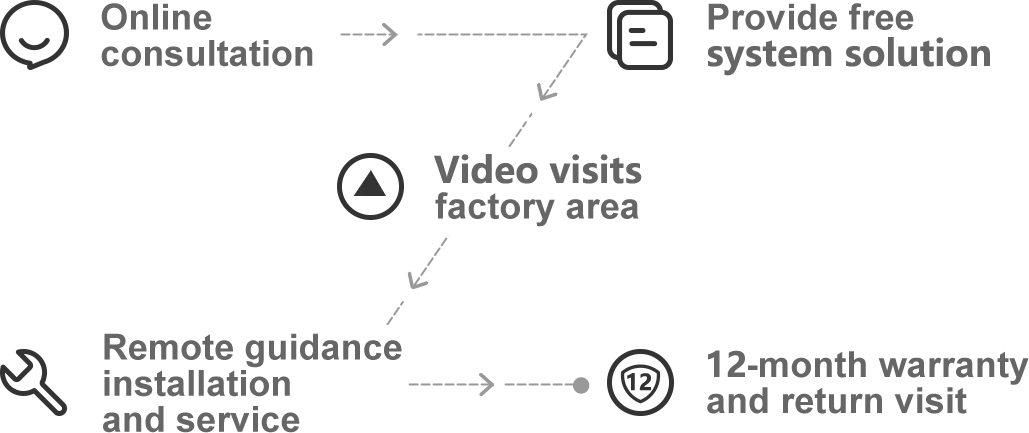

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!